Kongsberg Automotive has, in co-operation with various commercial vehicle manufacturers, developed a new air coupling system based on composite material and brass for use with plastic tubing for the compressed air circuits used on commercial vehicles.

The use of our couplings with other media than air is not permitted without prior approval.

Raufoss ABC™ couplings can be used with polyamide (PA 11 /PA12) or Hytrel tubing to one of the following standards:

Operating temperature for ABC™ Couplings is between -40°C to+100°C, with peak-temperature up to + 130°C (pressure less, for a period of approximately 2 hours.)

The operating pressure is max 15bar for the couplings. Please take into consideration the max allowed tube operation pressure.

Raufoss ABC™ couplings from Kongsberg Automotive is approved and certified by: TÜV Nord

For any further specific requirements, applications of our product or support for technical solutions, please ask for a member of the sales team at Cable Controls.

We offer a wide range of configurable options to match your exact setup:

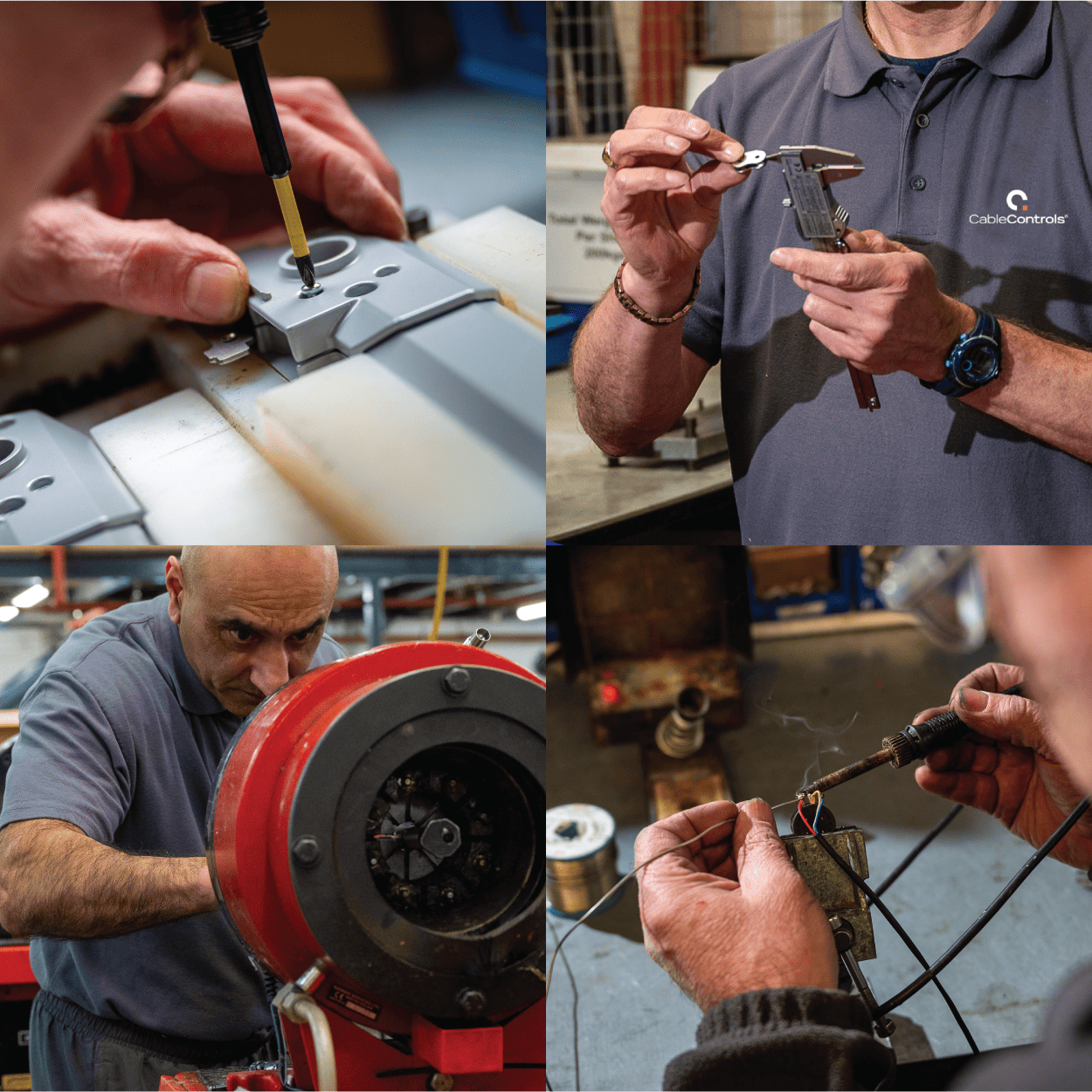

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.