These ball joints are constructed from durable materials such as steel, stainless steel, or reinforced polymers, often with low-friction liners or protective coatings to ensure smooth motion, corrosion resistance, and long service life. The design can include snap-fit or threaded connections for easy assembly and maintenance, and optional features such as dust seals, quick-disconnect mechanisms, vibration damping, and angle-limiting stops to enhance performance in demanding environments.

Customisable options include ball and socket sizes, material selection, load ratings, articulation angles, and environmental protection, making them suitable for automotive, industrial, marine, and aerospace applications where reliable and precise control cable operation is critical.

Material: Body and ball stud Low carbon steel.. Case hardened. Inner retaining ring Hard drawn spring steel to SAE1070 or equivalent

Protective Finish: Body and ball stud Zinc plated, de-embrittled and passivated. Inner retaining clip Self-colour. The assembly is lubricated.

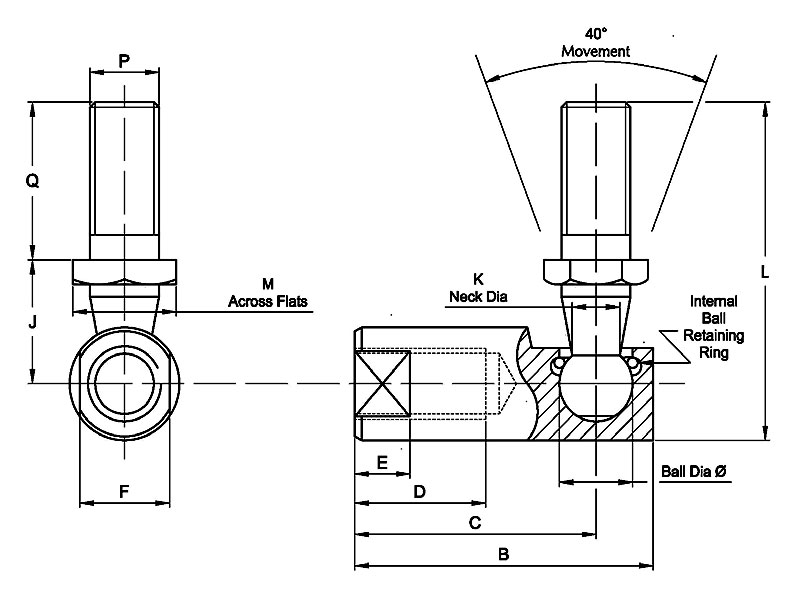

Metric equivalent to SAE J 490 style 4.

Ball stud is retained by a hardened and tempered steel ring resulting in high pull-out load. There is an optional gaiter available to help resist dirt ingress.

The FM Ball Joint is ideal for severe wear conditions and is also resistant to vibration and high shock loading.

Inch sizes of this range are also available.

FM6

FM8

FM10

FM12

If a fitted gaiter is required then the suffix “G should be added to the part number. E.g FMG10.

We offer a wide range of configurable options to match your exact setup:

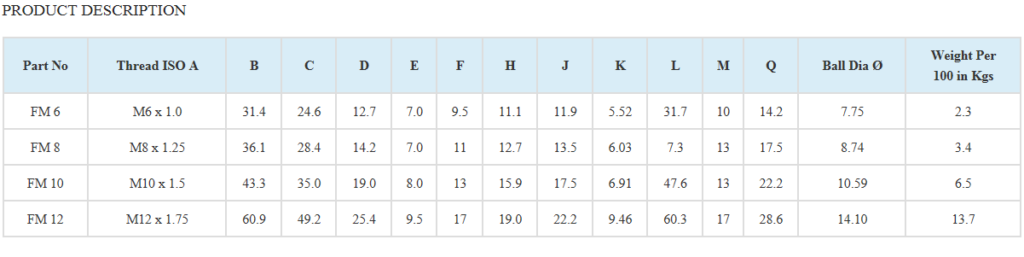

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.