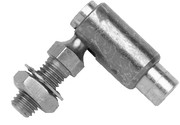

Cable Controls can supply a full range of standard Metric Clevises. We can also manufacture custom designs to your requirements.

Material: Low Carbon Steel

Protective Finish: Zinc Plated and Passivated

Based on Din Standard 71752.

Clevises are machine for precision.

31125, 202941, 213498, 31800, 202942, 213649, 215146, 29025, 202944, 202782, 42212, 215149, 202778, 45985, 215151, 29132-001, 215145, 38820, 215147, 43034, 215148

We offer a wide range of configurable options to match your exact setup:

Thread type & length

Custom male or female thread types (metric, UNC, UNF, etc.)

Extended or shortened threaded shank for deeper adjustment range.

Material & finish

Stainless steel for marine or corrosive environments.

Aluminum for lightweight applications.

Coatings like zinc plating, powder coat, or anodizing for extra durability.

Cable integration

Swaged or crimped connections for permanent attachment.

Detachable clevis with set-screws or clamps for field replacement.

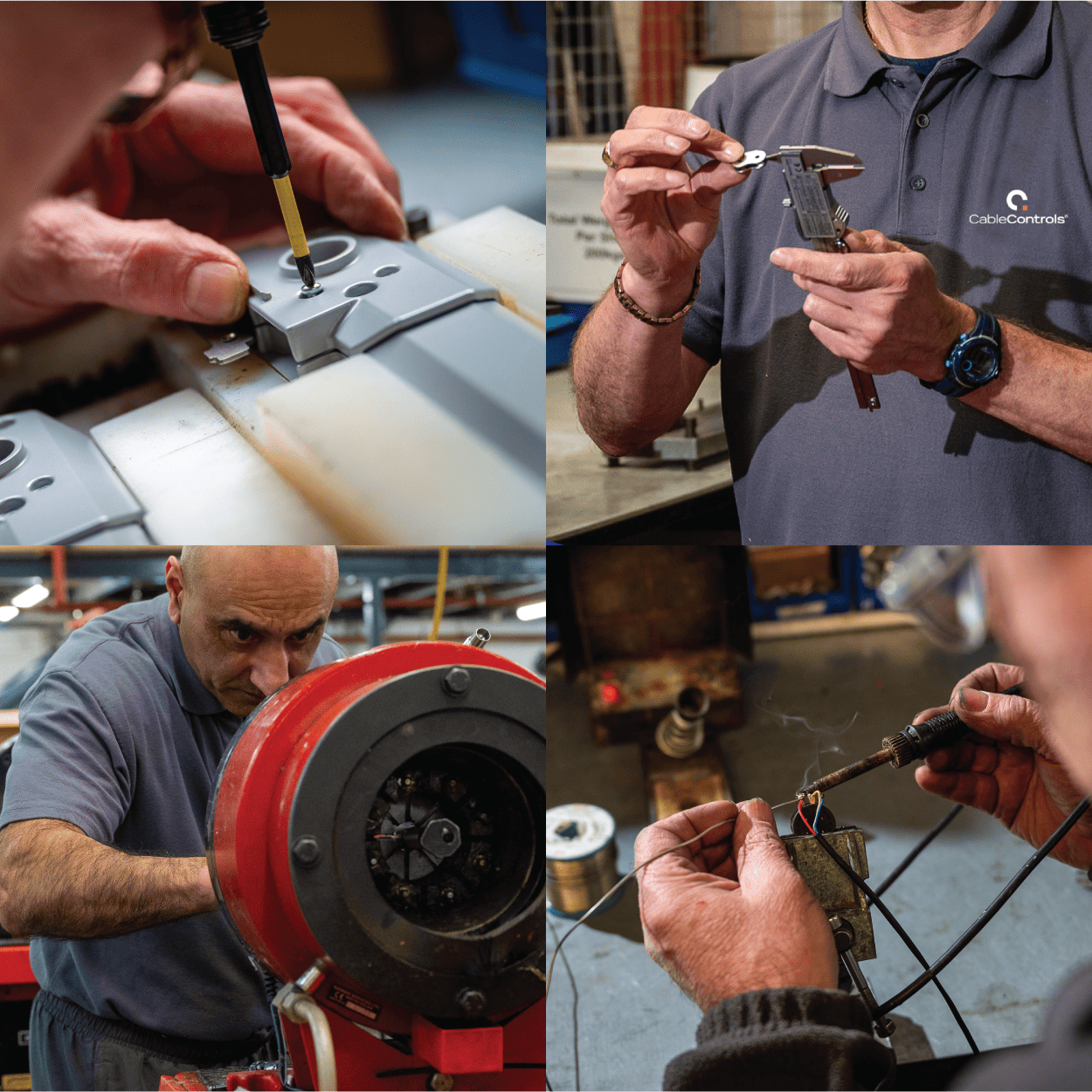

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Need something custom?

We offer bespoke

cable assemblies.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.