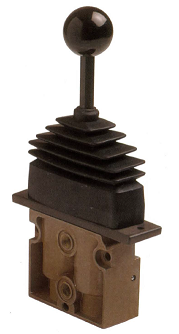

The dual valve consists of a die-cast valve body containing two pneumatic reducing valves operated by a handle and a rocket arm.

The pressure reducing valve used in these assemblies is a three-way type and has low hysteresis.

Moving the lever out of centre position, results in an increasing pilot pressure, proportional to the lever position.

The pilot pressure controls the servo cylinder or the pool control in the hydraulic directional valve. Moving the lever back to the centre position will reduce the pressure and exhaust the air through the valve.

Advantages and Applications

Dual and Quad valves are single and dual axis, pneumatic servo control valves, used mainly for controlling hydraulic directional valve and pump actuators in mobile applications.

This type of valve is used for remote control in applications not requiring the very high precision offered by an electronic control system.

The system improves the operator comfort and also give the designer a freedom of choice when locating the hydraulic components. The system is in expensive and easy to install.

Typical applications are fork lift trucks, dump trucks, refuse vehicles and hook loaders.

Design and Function

The range of pneumatic servo valves includes a number of different options, such as:

Valve with single axis lever, for one double-acting function.

Valve with dual axis lever, for two double-acting functions.

Single axis valves, block-mounted, for up to eight double-acting functions.

Levers with electric switches.

Levers with pneumatic sequence valve.

Valves with mechanical detent in different positions.

Technical Specification

Max. supply pressure: 10 bar

Max. pilot pressure: 7 bar

Flow capacity at 6.9 bar: 350 NI/min

Ports: 1/8 -27 NPTF

Temperature range, surrounding: -30 / +100C

Material in valve body: Aluminium

Weight, Dual Valve: 0.60kgs

Weight, Quad Valve: 1.30kgs

Mounting position: Optional

866000,

866250,

866900,

225834

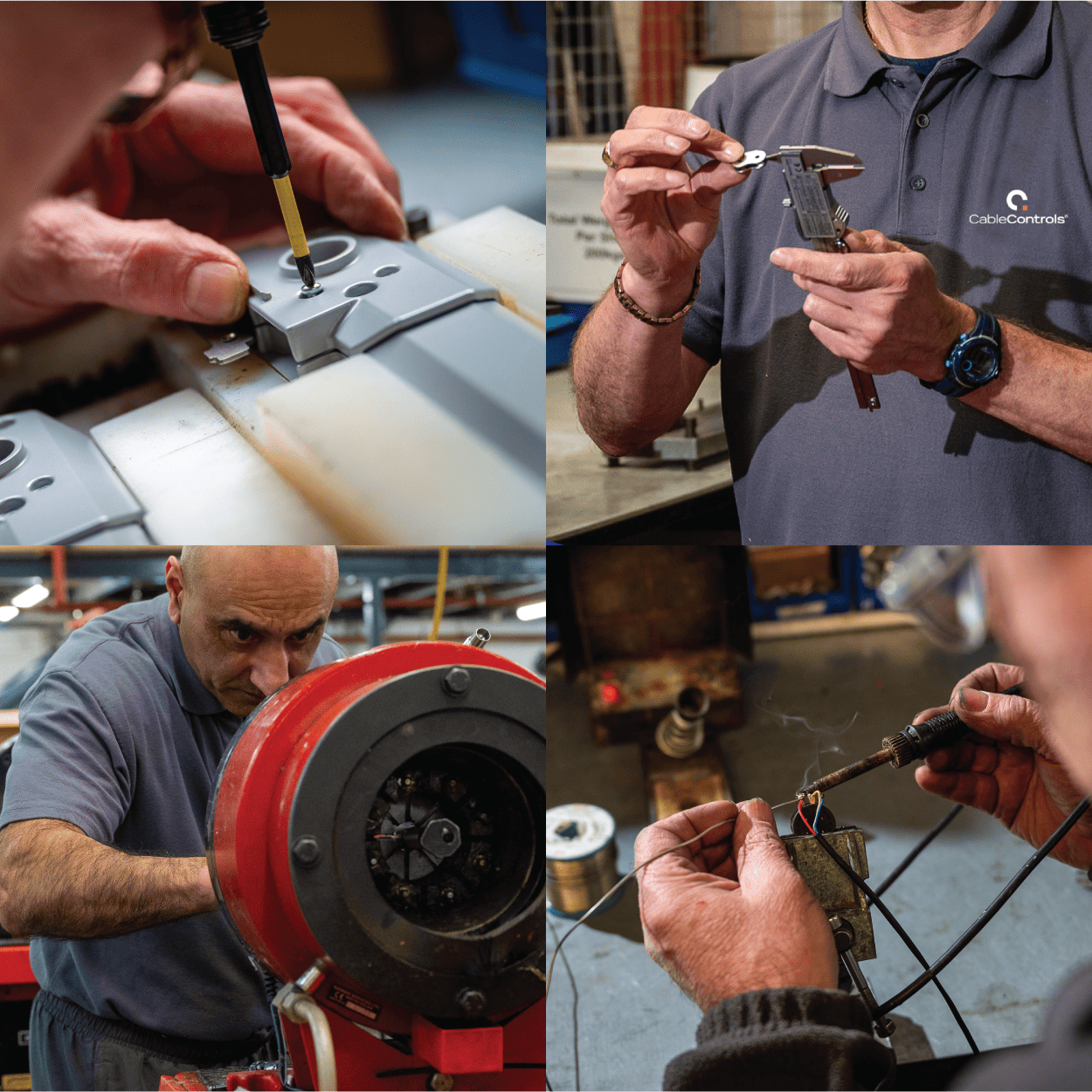

We offer a wide range of configurable options to match your exact setup:

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.