Control Controls are distributors for Kongsberg Automotive Power Product Systems and have access to supply compressed air coupling branded as Raufoss CouplingsTM. These compressed air couplings meet all applicable industry standards and are fully optimised for minimum pressure loss, a lasting, temperature-independent sealing function, compact external dimensions, and cost-efficiency.

Using Raufoss CouplingsTM, customers can choose between complete systems of plug-in, push-in, and push-to-connect solutions. A wide range of dimensions are available for fir tree, straight push-in and cartridges. In addition, the systems include manifolds, multi-connectors, test points, etc. High flexibility and modularity facilitate full compliance with system design requirements while reducing the number of parts.

Extensive development activities and more use of polymer technology will ensure fulfillment of customer expectations today and in future. Our team of specialists provides key account service and technical support to achieve fully optimized, cost-effective system solutions.

Raufoss Couplings

The carefully developed, technically superior Raufoss couplingsTM system consists of the following elements:

Raufoss couplingsTM system can be used with polyamide or hytrel tubing to one of the following standards:

This tubing is available at Hindle Controls in all sizes to fit Raufoss Couplings along with different colours for different applications.

The couplings´operating temperature is between -40°C to +100°C, with peak-temperature up to +140°C (for a period of approximately 2 hours.)

The operating pressure for the couplings meet with the requirements for non metallic tubes. All brass components are manufactured from (CuZn40Pb2/CuZn39Pb3) in compliance with DIN 17600, unless otherwise specified. All steel components are manufactured from 9SMnPb28 in compliance with DIN 1651 and yellow chromated acc. ISO 4042/A3C. See separate notes in the catalogue. All o-rings are manufactured from EPDM. The use of our couplings with other media than air is not permitted without prior approval.

Kongsberg Automotive has been approved and certified by the following organisations:

Kongsberg Automotive´s quality system is approved according to the following international standards:

For any further specific requirements, applications of our product or support for technical solutions, please ask for individual consultation from Hindle Controls,.

Product List

We offer a wide range of configurable options to match your exact setup:

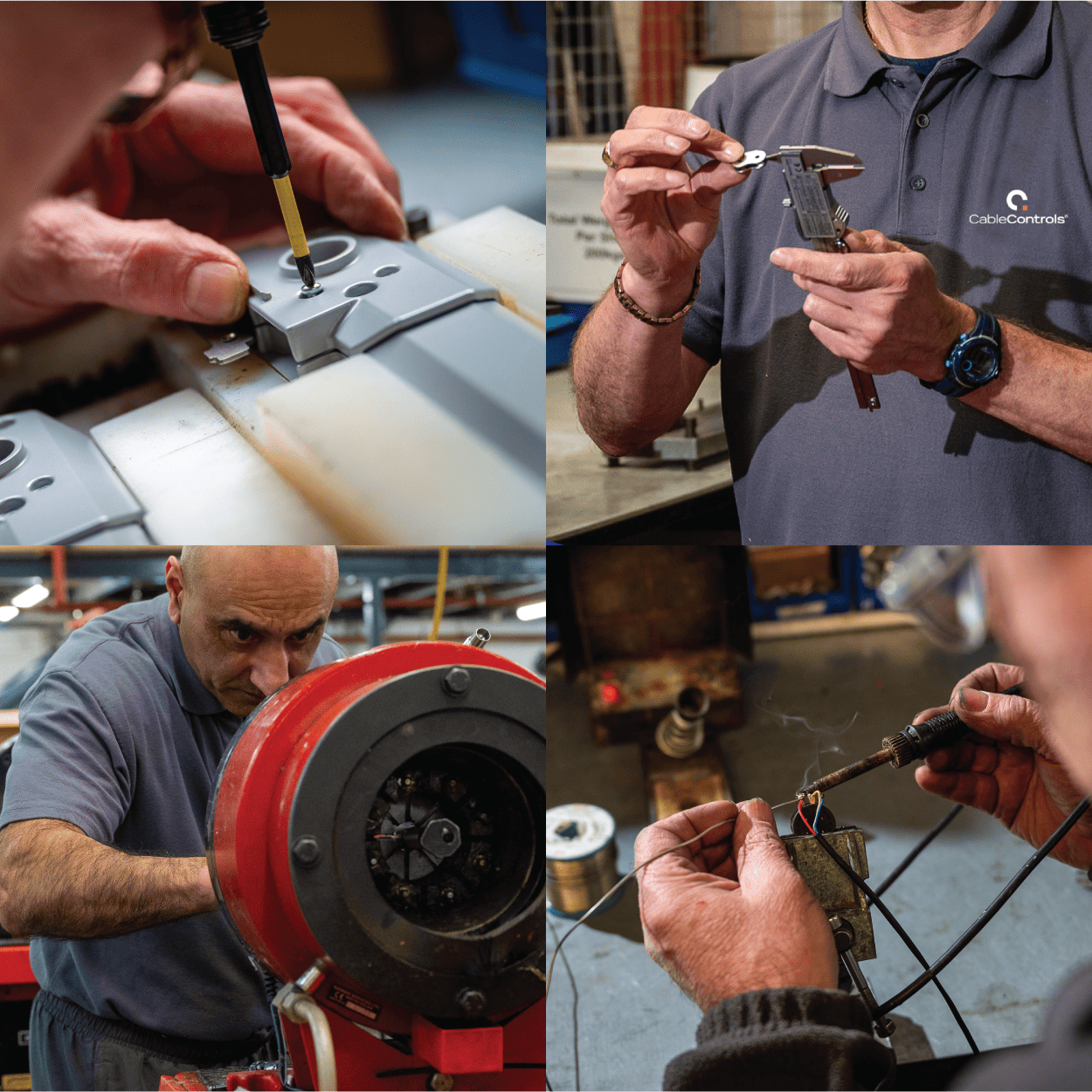

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.