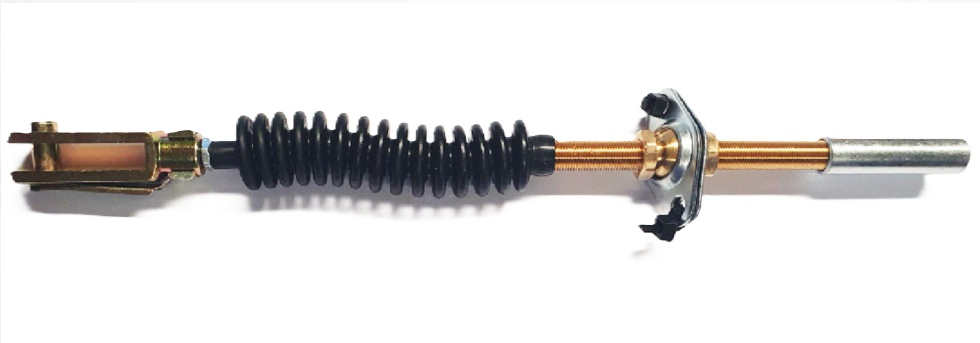

A mechanical mixer cable (push–pull type) is a flexible, mechanical control cable designed to transmit linear force in both pushing and pulling directions. Unlike an electrical cable, it works on the principle of a core sliding within a protective outer casing, allowing an operator to control a function (e.g., throttle, clutch, drum tilt) remotely and smoothly.

Cable Controls can manufacture any length you require in metres or feet. We can also supply the Concrete Mixer Controls to suit these Mixer Cables.

Construction:

Inner Core: High-tensile steel wire or stranded cable, engineered to carry compressive (push) and tensile (pull) loads.

Liner: Low-friction polymer or nylon sleeve that reduces wear and ensures smooth motion.

Outer Casing: Spiral-wound steel with a protective plastic or rubber jacket for strength, flexibility, and durability.

Operation: Transfers operator input directly to mechanical components (like a lever or linkage) without the need for hydraulics or electronics.

Flexibility: Designed to bend around obstacles while maintaining motion transfer.

Durability: Resistant to dirt, moisture, vibration, and mechanical wear — critical for construction site environments.

End Fittings: Usually threaded rods, clevises, or ball joints, allowing easy attachment to mixer controls.

Applications in a Concrete Mixer:

Controlling the tilt or discharge of the drum.

Engaging/disengaging a clutch or brake mechanism.

Adjusting a throttle or governor on engine-driven mixers.

FL0602

We offer a wide range of configurable options to match your exact setup:

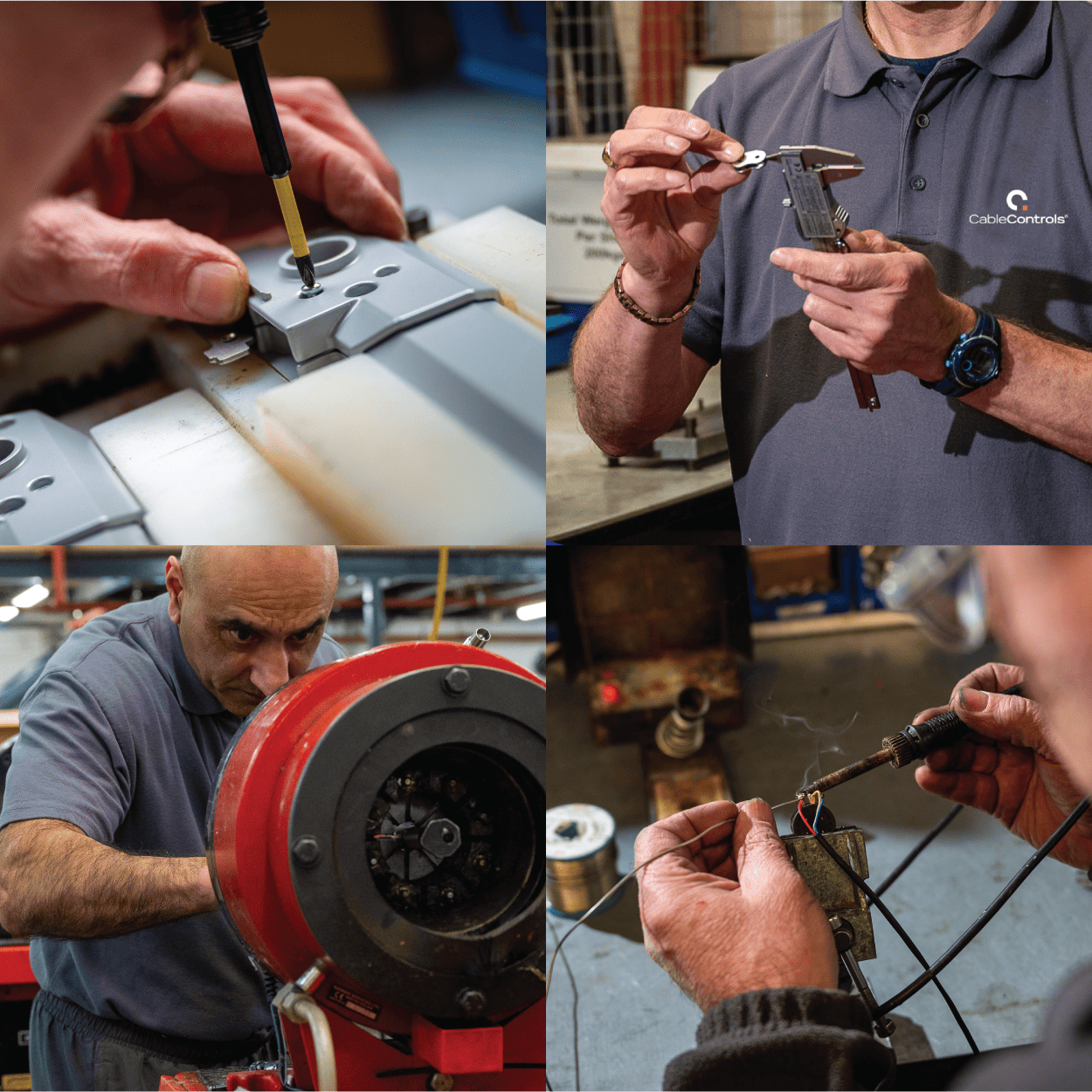

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.