Mechanical heater cables, also known as Bowden heater control cables, are flexible mechanical transmission elements used to transmit push–pull or pull-only motion between a control lever and a heater system. They are widely used in automotive HVAC systems, industrial machinery, agricultural equipment, and marine applications where reliable mechanical control is required.

In summary, mechanical heater cables (Bowden type) are precision-engineered motion transmission devices that provide smooth, reliable control of heating and ventilation components across automotive, marine, agricultural, and industrial applications.

We offer a wide range of configurable options to match your exact setup:

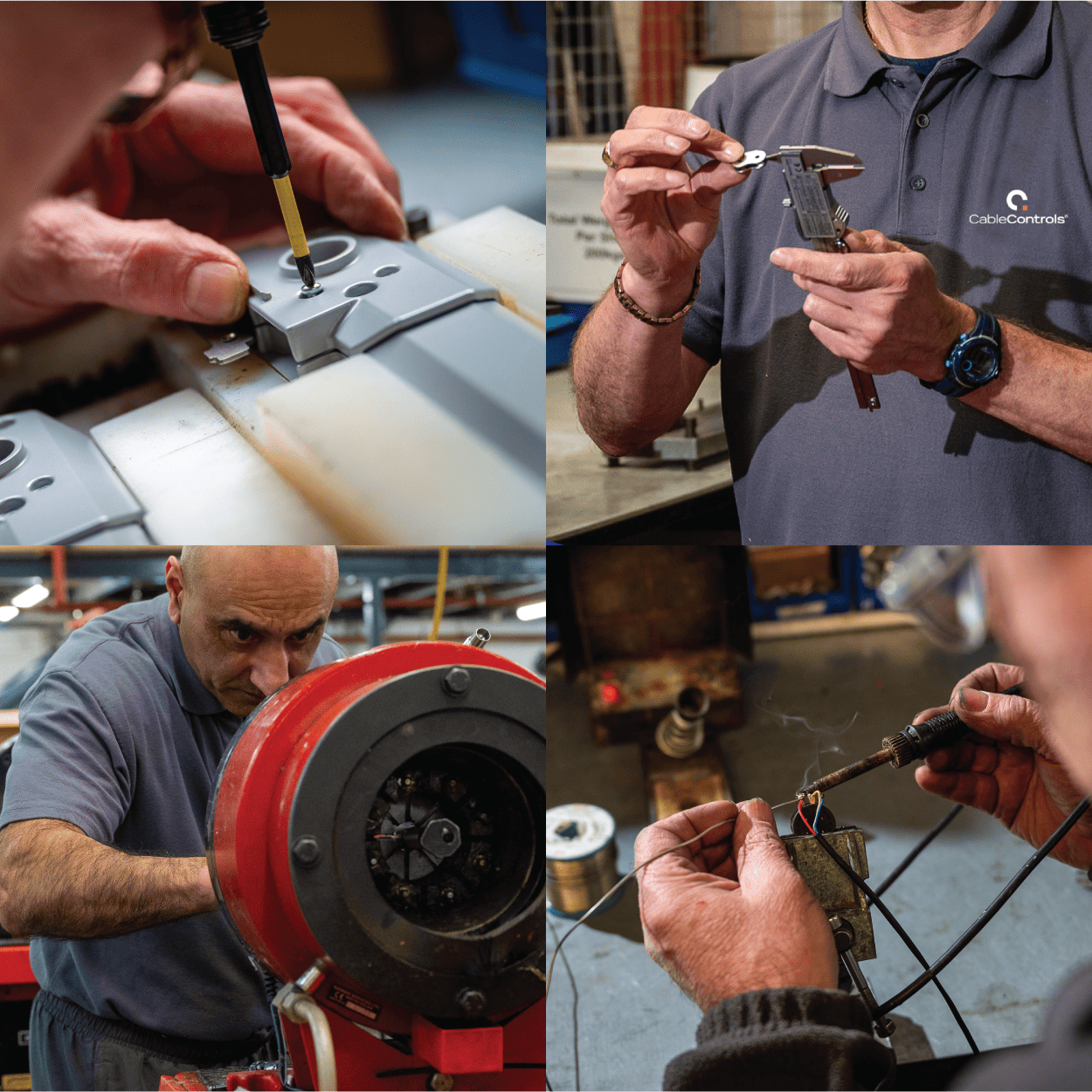

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.