The WVGA (800×480) TFT LCD colour display can be viewed in full sunlight, has the potential for multiple screens to be displayed via user defined touch screen buttons, and supports external buttons/joystick controls. The complete unit is sealed to meet IP standards 66 (front) & 67 (rear).

It meets the need for tough, flexible instrumentation that will handle the harshest environments and where a larger display is essential. Custom applications to be rapidly created using the CANvu software development kit (SDK). The display can provide system control functions, alarm functionality, and has configurable data logging capability.

CANvu products continue to be successfully deployed in an enormously diverse range of applications where total reliability is vital.

All products, bespoke or standard range are backed up by a dedicated central team of specialist engineers able to rapidly adapt any product for a specific application and to provide an unrivalled level of customer support.

The CANvu displays are also supported with a return to base extended 24-month Manufacture warranty against mechanical failure or material defects.

Our SDK is offered for a one-off licence fee from which customers can develop their own bespoke application solution. Available are optional plugins for CANopen, J1939, NMEA 2000, and support hours are included should your engineers need any help along the way.

Alternatively, Hindle Controls can develop bespoke software to your specification using our experienced in house engineers.

Over the years our engineers have developed software for our displays to run rock crushers & mining machinery, measure performance of spraying equipment, acting as battery monitors, boat gyro stabilisers, plus many more including military and aerospace applications.

Also available is our CANvu™ Engine Monitor standard software for Industrial and Marine, which can be pre-loaded to our displays receiving and displaying J1939 engine and transmission data, including common Tier4 parameters, with active alarms (from DM1) & NMEA 2000 data, where supported.

We offer a wide range of configurable options to match your exact setup:

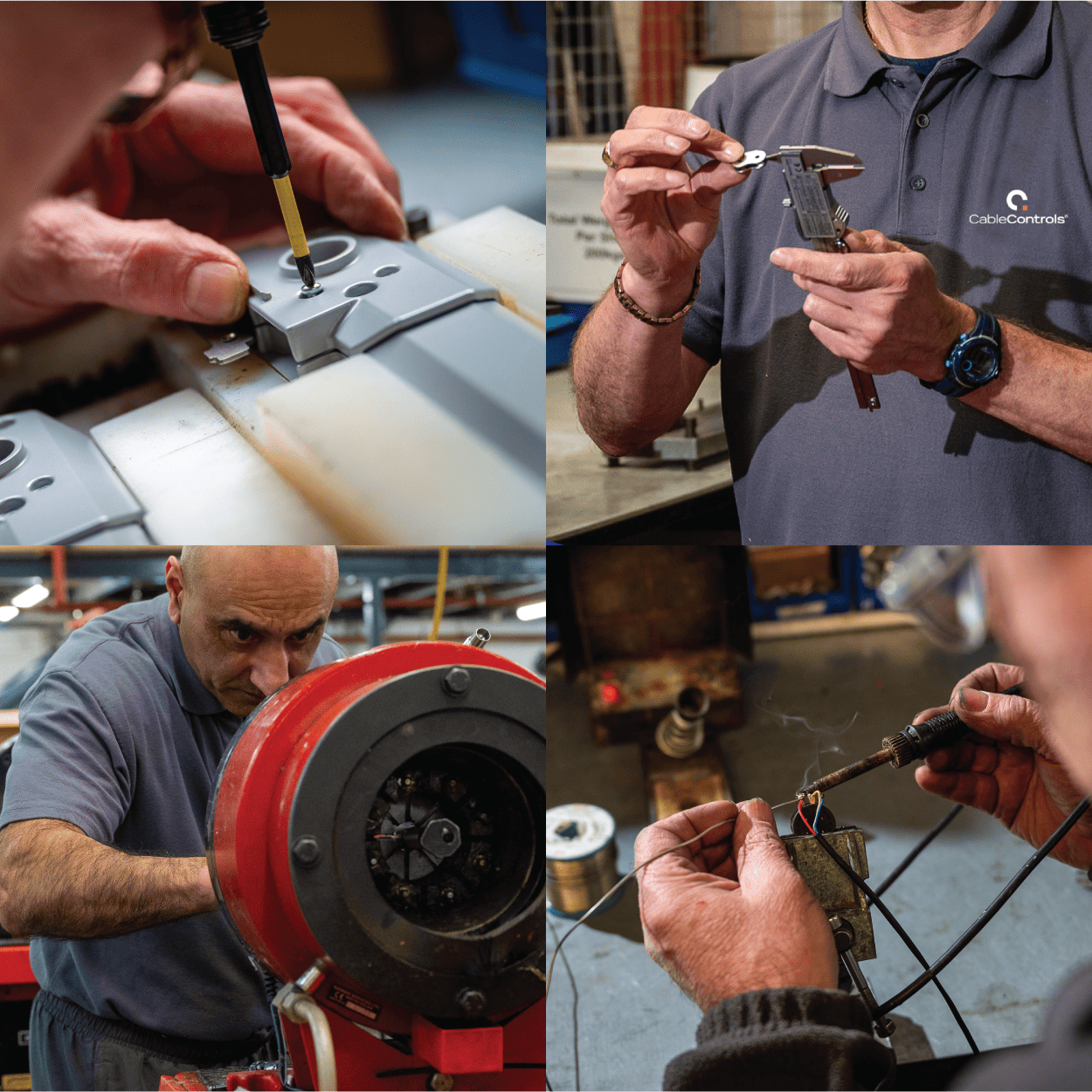

We work with you from concept to completion, helping you replace legacy parts or develop custom systems.

Our engineers provide CAD-based configuration, prototyping, and testing to ensure your cable works perfectly the first time. We also offer push-and-pull testing as standard, with lifecycle testing available on request. For urgent projects, same-day or next-day turnaround can be arranged to keep your production schedules moving.

Services available:

CAD design, prototyping, push-and-pull testing, lifecycle testing (on request), plus same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

CAD design,

Prototyping,

Push-and-pull testing,

Lifecycle testing (on request),

Same-day and next-day turnaround to support urgent marine, industrial, or specialist engineering projects.

Need something custom?

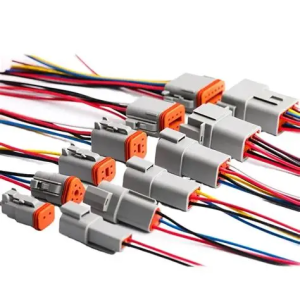

We offer bespoke

cable assemblies.

Have a question or need a custom solution? Fill out the form below and our expert team will get back to you with the answers and support you need to succeed.

Hindle Controls has become the Cable Controls group.

The same trusted team, with the same commitment to precision, refreshed to reflect the breadth of what we do.